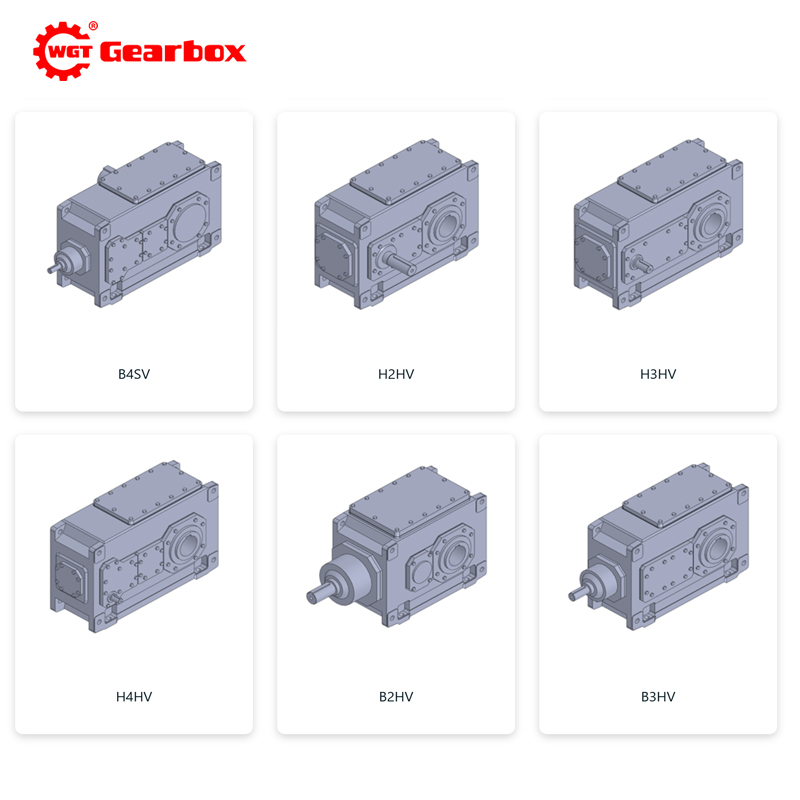

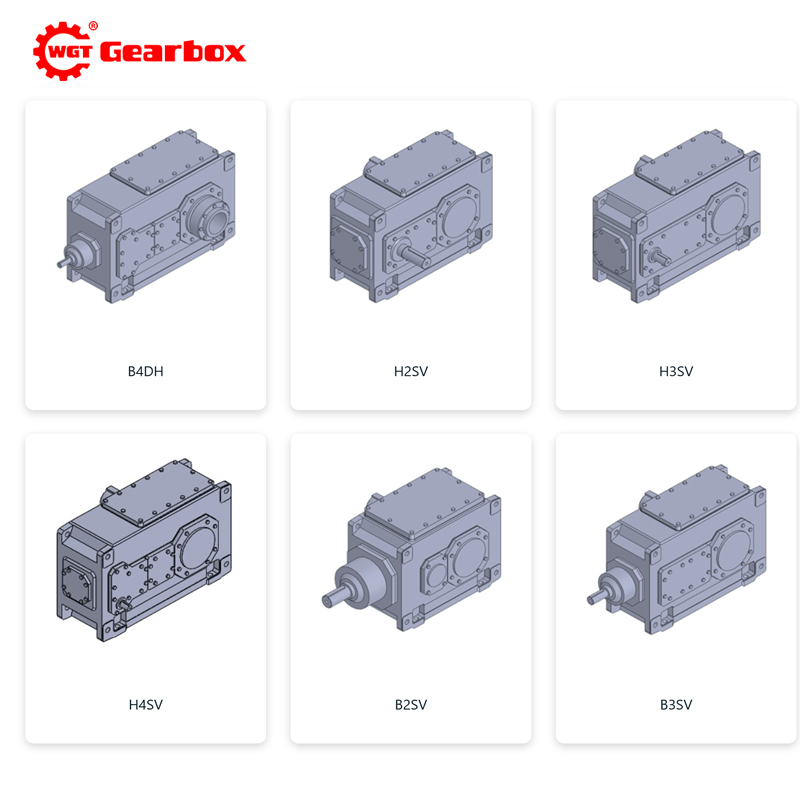

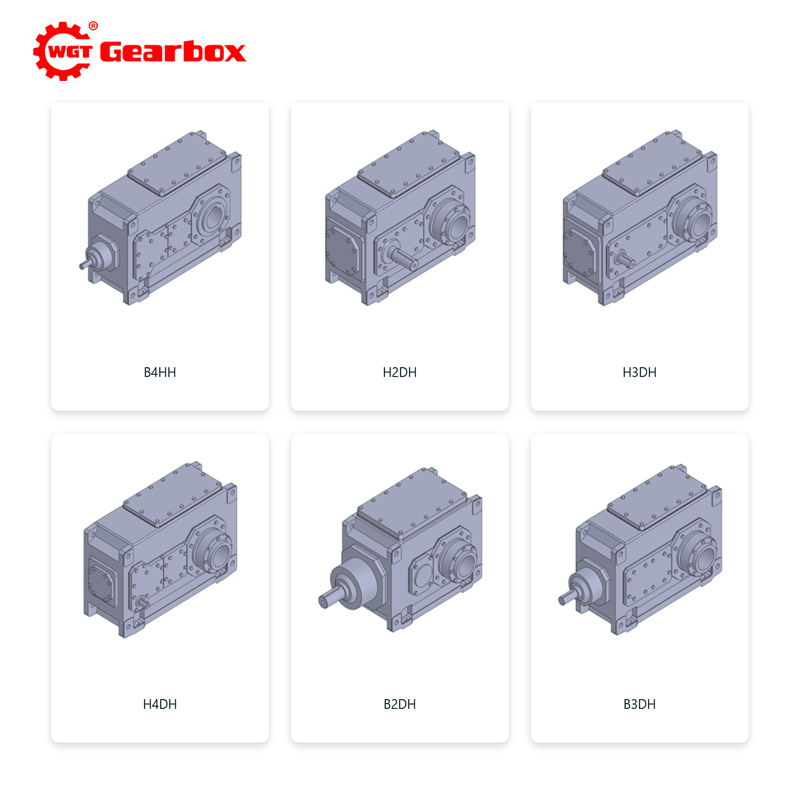

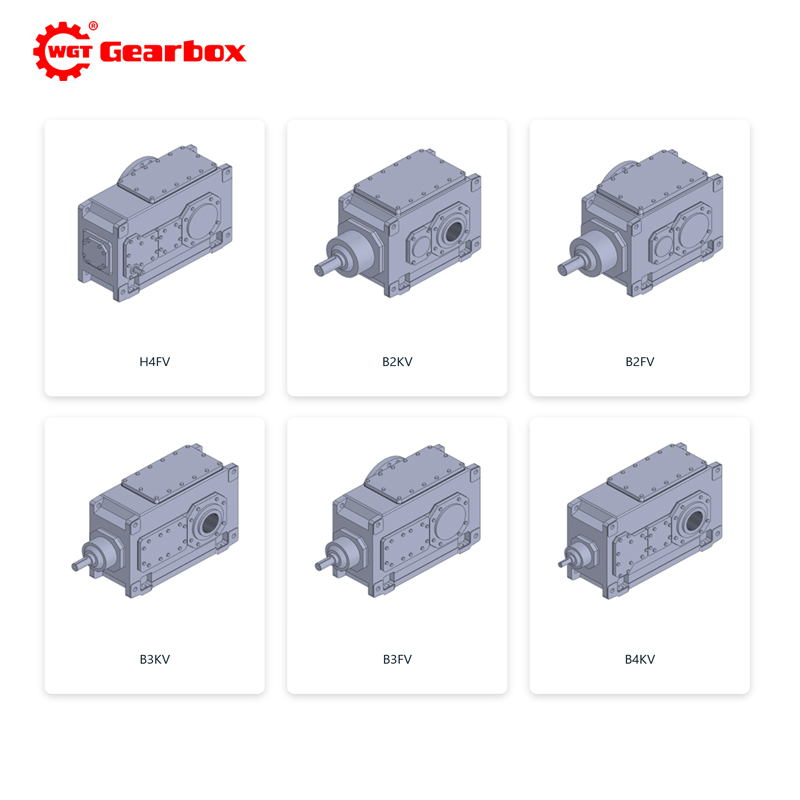

HB-Series Industrial Gear Reducer (H4FV/B2KV/B2FV/B3KV/B3FV/B4KV): Low-Temperature Resistant & Corrosion-Proof, Enabling Energy-Saving Operation in Complex Extreme Environments

I. Product Overview: Low-Temperature & Corrosion-Proof Graded Configuration, Meeting Complex Extreme Environment Transmission Needs

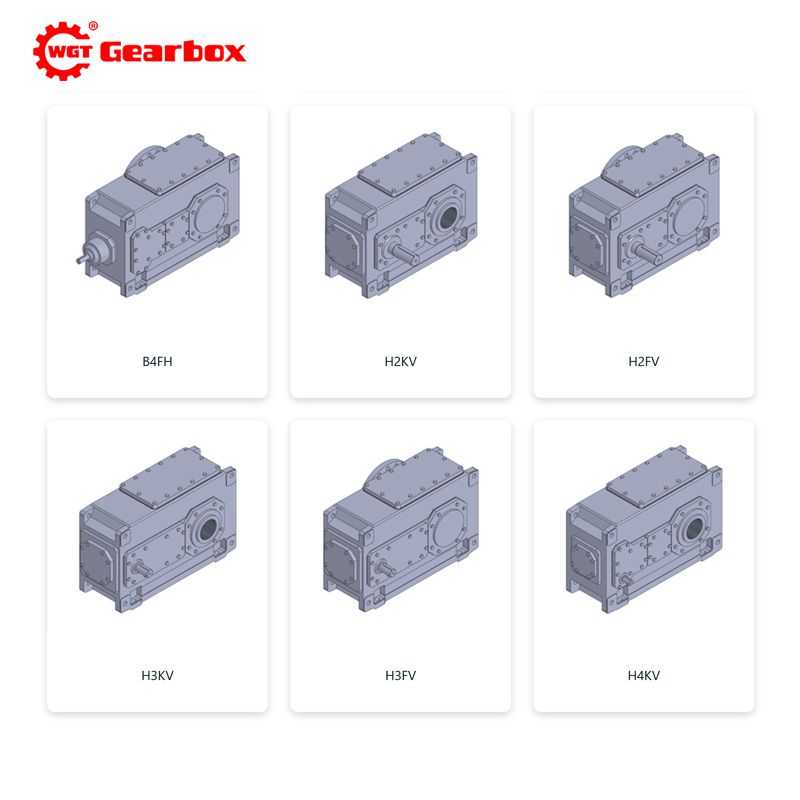

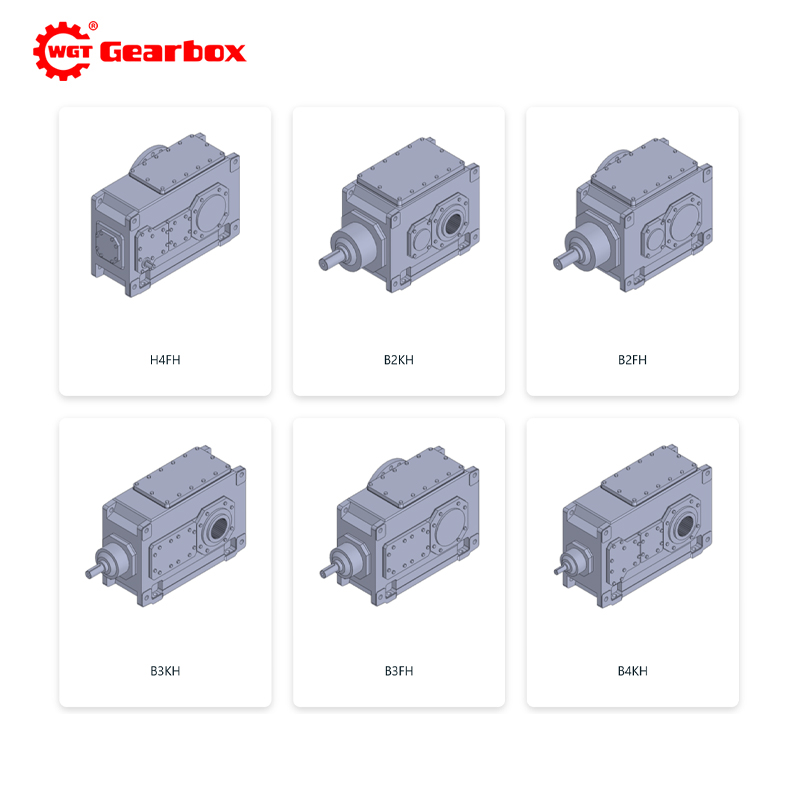

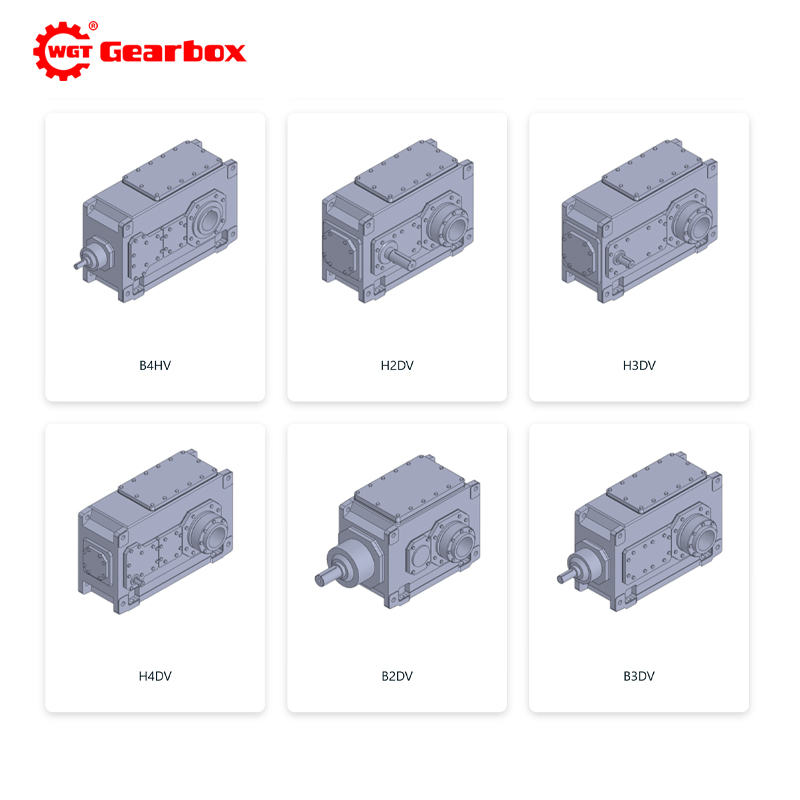

Weigao’s HB-Series Industrial Gear Reducer, covering core models H4FV, B2KV, B2FV, B3KV, B3FV and B4KV, is a high-reliability power transmission device specialized in core industrial scenarios requiring low-temperature resistance, corrosion protection, energy-saving operation and stable work in complex extreme environments. Based on an upgraded dual-series (KV/FV) low-temperature adaptive & corrosion-proof configuration design platform, this series integrates advanced energy-saving helical gear technology, enhanced low-temperature resistant structural design, multi-layer corrosion-proof material modification and intelligent modular assembly technology, realizing an excellent balance of graded low-temperature adaptation, high-efficiency torque transmission, corrosion protection and energy-saving operation. It effectively solves the pain points of traditional reducers such as poor low-temperature toughness, weak corrosion resistance, high energy consumption and easy failure under alternating cold-heat and corrosive medium environments, and can maintain stable and efficient power output in working conditions involving heavy load, continuous operation, ultra-low temperature, corrosive medium and large temperature fluctuation. With its low-temperature resistant, corrosion-proof advantages and intelligent energy-saving performance, it has become a core transmission component in industries such as polar engineering, marine engineering, petrochemical offshore platforms, cold-region mining and refrigeration logistics, providing high-reliability and energy-saving power support for heavy-duty industrial production in complex extreme environments. As a high-end extreme environment-adapted product of Weigao, this series has passed international low-temperature and corrosion-resistant certifications, serving key projects in more than 60 countries and regions, and winning wide recognition for its environmental adaptability and energy-saving value.

II. Core Advantages: Six Core Strengths, Shaping Heavy-Duty Transmission Benchmarks

1. Energy-Saving Precision Helical Transmission, High-Efficiency & Stable

Adopting precision-ground energy-saving helical gears with optimized tooth profile and low-friction modification, high-strength lightweight modulus design, advanced multi-stage carburizing quenching technology and low-temperature resistant nitriding treatment, the series achieves meshing accuracy up to GB/T 10095.2 Class 4 standard. The parallel-axis helical transmission structure with reinforced rigid rib, low-temperature resistant wall and optimized heat dissipation design ensures smooth and uniform meshing between gears, balanced force distribution and minimal energy loss, reducing transmission backlash to ≤2.0arcmin. The transmission efficiency reaches 97%-99% for single-stage transmission and 95%-98% for multi-stage transmission, which is 3%-5% higher than that of traditional reducers, effectively reducing energy consumption in long-term heavy-duty operation. The fully enclosed integral cast steel housing with integrated anti-corrosion coating and low-temperature toughening treatment combines excellent structural rigidity, low-temperature toughness and heat dissipation functions, with operating noise ≤68dB at 1m distance, ensuring high-efficiency and stable operation even in ultra-low temperature, corrosive medium and large temperature fluctuation environments.

2. Dual-Series Low-Temperature & Corrosion-Proof Graded Configuration, Precise Environment Adaptation

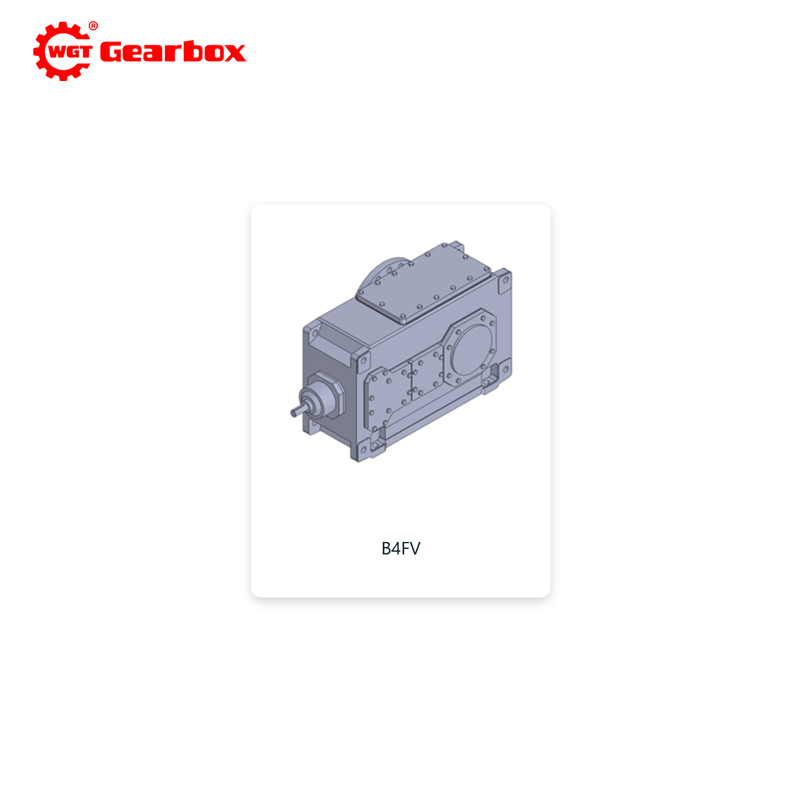

The six core models of the series are divided into KV and FV dual low-temperature resistant & corrosion-proof series with targeted graded configuration to meet differentiated complex environment transmission needs: KV-series models (B2KV, B3KV, B4KV) are standard low-temperature & basic corrosion-proof models, integrating high-strength low-temperature resistant material and basic anti-corrosion structure, suitable for general extreme environment heavy-duty equipment such as cold-region mining conveyors, land-based petrochemical transfer pumps and low-temperature logistics conveying systems; among them, B2KV is small-medium torque low-temperature model, B3KV/B4KV are large torque low-temperature enhanced models. FV-series models (B2FV, B3FV, H4FV) are ultra-heavy load low-temperature & enhanced corrosion-proof models with reinforced low-temperature resistant shaft, anti-corrosion wear-resistant gear, high-precision low-temperature bearing and integrated intelligent temperature monitoring design, ideal for ultra-heavy-load complex extreme environment equipment such as polar engineering machinery, marine offshore cranes, petrochemical offshore platforms and deep-sea exploration auxiliary equipment. This dual low-temperature & corrosion-proof series graded design ensures precise matching of different heavy load levels, low-temperature grades and corrosion medium requirements, further improving equipment operation stability and service life in complex extreme environments.

3. Ultra-High Torque & Low-Temperature Bearing Capacity, Durable Extreme Operation

Gears and transmission shafts are made of high-strength 20CrMnTi alloy steel with low-temperature toughening treatment (KV-series) and 17CrNiMo6 ultra-high-strength alloy steel with multi-layer anti-corrosion & low-temperature treatment (FV-series) , processed through precision forging, multi-stage low-temperature heat treatment, precision grinding and anti-corrosion coating processes (including ceramic anti-corrosion coating and zinc-nickel alloy plating). The surface hardness reaches HRC 62-65, and the core hardness is HRC 38-42, ensuring excellent low-temperature toughness, super load-bearing capacity, corrosion resistance and torque transmission stability even under long-term ultra-low temperature (-55℃), corrosive medium and alternating cold-heat environments. The optimized gear modulus, tooth width, shaft diameter and low-temperature resistant structure design for each model ensures that the rated output torque of the series is precisely graded from 2800N·m to 50000N·m (B2KV: 2800-6000N·m; B3KV: 6000-22000N·m; B4KV: 22000-40000N·m; B2FV: 28000-38000N·m; B3FV: 38000-45000N·m; H4FV: 45000-50000N·m). The integral cast steel housing with high rigidity, thickened wall and low-temperature resistant design ensures no deformation or brittle fracture under ultra-heavy load and extreme low-temperature impact, ensuring a service life of more than 20 years under normal maintenance in complex extreme environments.

4. Modular Intelligent Installation, Flexible Complex Layout Adaptation

The series adopts an upgraded modular intelligent design, supporting multiple installation modes such as base-mounted with low-temperature insulation pad, flange-mounted (B5/B14) with anti-corrosion seal, torque arm-mounted with shock absorption buffer, shaft-mounted with quick coupling, flange-output mounted and mobile base-mounted with temperature adaptive shock absorption, which can be flexibly selected according to the diversified layout requirements of complex extreme environment equipment. The output shaft is configured with ultra-heavy-duty reliable options such as extra-large-diameter low-temperature resistant solid shaft with flat key, high-strength anti-corrosion spline solid shaft, extra-large-torque hollow shaft with locking disk and wear-resistant anti-corrosion sleeve-equipped shaft. It can be precisely matched with motors with power ranging from 15kW to 500kW and reduction ratios of 8-550 (single-stage/multi-stage combination). The standardized intelligent interface design with reinforced anti-corrosion connection parts and low-temperature protection facilitates quick installation, replacement and debugging in polar regions, offshore platforms and cold-region mines, reducing construction difficulty and time cost, and adapting to the layout needs of various complex extreme environment core equipment.

5. Enhanced Anti-Corrosion Sealed & Low-Temperature Heat Dissipation, Wide Environment Adaptability

Equipped with a nine-layer enhanced anti-corrosion sealed system composed of heavy-duty low-temperature resistant double-lip oil seal, labyrinth seal with anti-corrosion coating, high-elasticity low-temperature resistant O-ring, low-temperature resistant sealant, stainless steel anti-corrosion dust-proof cover and anti-impact gasket, the reducer achieves IP68 anti-corrosion protection level (customizable for deep-sea immersion environments). This sealing structure can effectively prevent the intrusion of seawater, corrosive gas, low-temperature frost and dust in complex environments, avoid oil leakage, internal component corrosion and frost blockage, and achieve long-term reliable anti-corrosion and low-temperature protection. The optimized internal oil circuit design with multi-point intelligent lubrication, high-precision anti-corrosion oil filter, low-temperature adaptive heater and large-area integrated heat dissipation fins on the housing ensures sufficient lubrication, impurity filtration, adaptive temperature adjustment and low-temperature protection of all transmission components during high-load, ultra-low temperature, corrosive medium and alternating cold-heat operation. The product can work normally in the operating temperature range of -55℃ to +130℃, adapting to most complex extreme working conditions such as polar engineering, marine offshore platforms, cold-region mines and petrochemical plants.

6. Intelligent Convenient Maintenance, Energy-Saving & Cost-Effective Operation

The modular intelligent structural design with low-temperature anti-corrosion protection makes component disassembly and maintenance more convenient, and the high interchangeability of spare parts between the same series reduces maintenance difficulty and time cost in complex extreme environments. The centralized and protected anti-corrosion oil filling port, oil drainage port, low-temperature resistant transparent oil level observation window with intelligent temperature monitoring function and built-in high-precision anti-corrosion oil filter facilitate daily lubrication management, real-time oil level and temperature monitoring, impurity cleaning and maintenance. It is recommended to use special low-temperature anti-corrosion industrial gear oil (320# for normal low-temperature, 460# for ultra-low temperature), which further enhances the low-temperature toughness, corrosion resistance and load-bearing capacity of internal components; the first oil change is after 1500 hours of operation, and regular maintenance and oil change are performed every 5000 hours thereafter. The high reliability, long service life, excellent low-temperature anti-corrosion capacity and high energy efficiency of the product effectively reduce the frequency of maintenance and replacement and energy consumption cost, significantly lowering the total operation cost of customers. In practical applications, it can help customers reduce energy consumption by 10%-15% compared with traditional reducers .

III. Application Fields: Complex Extreme Environment Coverage, Boosting Energy-Saving Industrial Production

With its dual low-temperature & anti-corrosion series graded configuration, ultra-high torque bearing capacity, intelligent installation adaptation, high-efficiency transmission and wide environment adaptability, Weigao’s HB-Series Industrial Gear Reducer (H4FV/B2KV/B2FV/B3KV/B3FV/B4KV models) has been widely applied in various complex extreme environment core industrial fields:

- Polar Engineering: Polar scientific research station equipment, polar ice-breaking ship auxiliary systems, adapting to ultra-low temperature (-55℃), strong wind and snow environment;

- Marine Engineering: Offshore oil drilling platforms, marine crane systems, shipborne conveyor equipment, adapting to seawater corrosion, high humidity and alternating cold-heat environments;

- Petrochemical Industry: Offshore petrochemical transfer pumps, corrosive medium conveyors, petrochemical reaction tower auxiliary systems, adapting to corrosive gas, high pressure and low-temperature environments;

- Cold-Region Mining: Arctic/Antarctic region mining machinery, cold-region coal conveyors, low-temperature mine hoisting equipment, adapting to ultra-low temperature, high dust and frozen soil environment;

- Refrigeration Logistics: Large cold storage conveyor systems, low-temperature logistics sorting equipment, frozen food processing lines, adapting to low-temperature (-30℃~-50℃), high humidity and clean environment;

IV. Technical Parameters: Precise Matching, Meeting Diverse Needs

| Item | Specification Range |

| Motor Power Adaptation | 15kW - 500kW |

| Reduction Ratio | 8 - 550 (Single-stage/Multi-stage Combination) |

| Rated Output Torque | 2800N·m - 50000N·m (Dual Low-Temperature & Anti-Corrosion Series Graded) |

| Transmission Efficiency | 95% - 99% (Single-stage/Multi-stage) |

| Operating Noise | ≤68dB (Measured at 1m Distance) |

| Protection Level | IP68 (Deep-Sea Immersion Customizable) |

| Operating Temperature | -55℃ - +130℃ |

| Installation Method | Base-mounted with Low-Temperature Insulation Pad, Flange-mounted (B5/B14) with Anti-Corrosion Seal, Torque Arm-mounted with Shock Absorption Buffer, Shaft-mounted with Quick Coupling, Flange-output Mounted, Mobile Base-mounted with Temperature Adaptive Shock Absorption |

| Output Shaft Type | Extra-Large-Diameter Low-Temperature Resistant Solid Shaft (Flat Key/Spline), High-Strength Anti-Corrosion Spline Solid Shaft, Extra-Large-Torque Hollow Shaft (Locking Disk), Wear-Resistant Anti-Corrosion Sleeve-Equipped Shaft |

V. Installation and Maintenance: Scientific Operation, Maximizing Performance

During installation, ensure that the coaxiality error between the reducer and the motor is ≤0.08mm to avoid affecting transmission efficiency, low-temperature performance and ultra-heavy load-bearing capacity. For ultra-heavy-duty, ultra-low temperature and corrosive environment installation, adopt reinforced installation base with low-temperature insulation layer and high-performance anti-corrosion buffer pads to reduce low-temperature impact and corrosion damage. Ensure that all connection parts are fully sealed and reinforced with low-temperature resistant sealant to avoid corrosive medium intrusion and loosening under extreme environment impact. Select the appropriate lubricating oil according to the working conditions: use 320# low-temperature anti-corrosion industrial gear oil for -30℃~-10℃ environment, 460# ultra-low temperature anti-corrosion industrial gear oil for -55℃~-30℃ environment. Regularly check the oil level, oil quality, gear meshing status, fastener tightness, heat dissipation fin cleanliness, oil filter blockage and anti-corrosion coating integrity; replace the lubricating oil after the first 1500 hours of operation, and perform comprehensive maintenance every 5000 hours thereafter for complex extreme working conditions, including checking bearing temperature, sealing performance, housing deformation, gear wear and low-temperature toughness status. If abnormal phenomena such as excessive noise, obvious vibration, oil leakage, overheating, torque fluctuation or frost blockage occur during operation, stop the machine immediately for inspection and troubleshooting.

VI. Conclusion: Low-Temperature & Anti-Corrosion Driven, Creating Complex Extreme Environment Transmission Value

Adhering to the design philosophy of "Low-Temperature & Anti-Corrosion Grading, Intelligent Energy-Saving, Complex Environment Adaptation and High Reliability", Weigao’s HB-Series Industrial Gear Reducer (H4FV/B2KV/B2FV/B3KV/B3FV/B4KV models) focuses on the stable and efficient transmission needs of complex extreme environment core industrial fields, and continuously optimizes product structure and low-temperature anti-corrosion technology. Whether in ultra-low temperature heavy-duty transmission, corrosive medium harsh operation or complex alternating cold-heat scenarios, this series can provide stable, efficient and energy-saving power transmission solutions for customers with its dual low-temperature & anti-corrosion series graded configuration, ultra-high torque bearing capacity and wide environment adaptation advantages, helping to improve production stability and energy-saving efficiency of complex extreme environment core equipment. We will continue to focus on the research and development of extreme environment adaptive transmission technology, deeply explore the needs of different complex extreme environment industrial fields, provide customized product solutions and global after-sales service support, and work with global customers to build a more reliable and energy-saving complex extreme environment industrial production system. All export products of this series have passed international certifications such as ROHS, CE, ISO9001 and low-temperature anti-corrosion certification, fully complying with the technical standards and safety requirements of various countries and regions for extreme environment equipment, ensuring smooth application in global complex extreme environment industrial markets.

Download

English

English