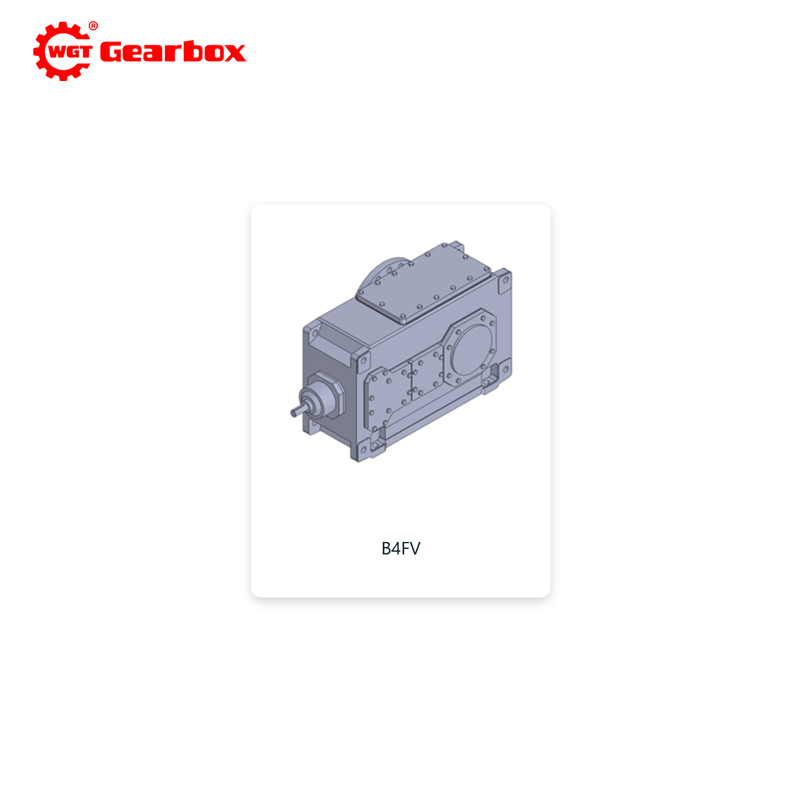

HB-Series Industrial Gear Reducer (B4FV): Heavy-Duty Impact-Resistant & Deep-Sea Grade Anti-Corrosion, Leading Extreme Heavy-Duty Transmission

I. Product Overview: Exclusive Design for Extreme Heavy-Duty, Breaking Through Harsh Environment Limits

Weigao’s HB-Series Industrial Gear Reducer B4FV is a high-end customized power transmission device exclusively developed for extreme heavy-duty scenarios with concurrent requirements of anti-corrosion, impact resistance and long-term stable operation. Targeting the pain points of traditional reducers such as insufficient impact bearing capacity, poor corrosion resistance and short service life in extreme heavy-duty environments like deep-sea operations and heavy mining, this model integrates advanced heavy-duty helical gear transmission technology, deep-sea grade multi-layer anti-corrosion modification and reinforced impact-resistant structural design. It realizes a perfect combination of ultra-high torque output, strong impact resistance, long-acting anti-corrosion and high transmission efficiency, and can stably operate in complex working conditions involving ultra-heavy load, frequent impact, corrosive medium (seawater/chemicals) and large temperature difference. As a core transmission component for key equipment in extreme heavy-duty fields, B4FV is widely applied in deep-sea oil and gas exploitation, large offshore engineering, heavy open-pit mining and other industries, providing reliable power guarantee for global extreme heavy-duty industrial projects. The product has passed international certifications such as DNV GL marine certification, ATEX explosion-proof certification and ISO 12944-6 C5-M deep-sea anti-corrosion certification, and is trusted by more than 40 countries and regions for its excellent extreme environment adaptability.

II. Core Advantages: Five Exclusive Strengths, Defining Extreme Heavy-Duty Standards

1. Reinforced Heavy-Duty Helical Transmission, Efficient & Impact-Resistant

Adopting precision-ground reinforced heavy-duty helical gears with optimized tooth profile and impact-resistant modification, the gear modulus is increased by 15% compared with standard models, and the meshing accuracy reaches GB/T 10095.2 Class 3 standard. The gears are made of 20CrNi2MoA ultra-high-strength alloy steel, processed by multi-stage carburizing quenching, low-temperature tempering and precision grinding, with surface hardness up to HRC 65-68 and core hardness HRC 40-45, ensuring excellent wear resistance and impact toughness. The parallel-axis helical transmission structure with reinforced gear shaft and integral rigid rib design realizes balanced force distribution during high-speed meshing, reducing transmission backlash to ≤1.8arcmin. The single-stage transmission efficiency is 97%-98.5%, and the multi-stage transmission efficiency is 95%-97%, which is 2%-3% higher than that of ordinary heavy-duty reducers. The operating noise is ≤65dB at 1m distance, and it can withstand 1.5 times the rated torque impact load for a long time, effectively adapting to the frequent impact working conditions of heavy mining and offshore hoisting.

2. Deep-Sea Grade Multi-Layer Anti-Corrosion, Long-Acting Protection

Adopting a 12-layer integrated anti-corrosion system developed for deep-sea environments, including zinc-nickel alloy plating (thickness ≥20μm), ceramic anti-corrosion coating, and fluoropolymer topcoat, which can resist seawater immersion, chemical corrosion and salt spray erosion for a long time. The housing is made of low-alloy high-strength cast steel with anti-corrosion modification, and undergoes strict salt spray testing (10000 hours no rust) and seawater immersion testing (5000 hours no corrosion). The sealing system adopts heavy-duty deep-sea special double-lip oil seal with anti-sediment design, combined with labyrinth seal and high-elasticity corrosion-resistant O-ring, achieving IP69K protection level and can be customized to IP68 deep-sea immersion protection (adapt to 500m deep sea environment). This multi-layer anti-corrosion design effectively solves the corrosion problem of reducers in offshore, chemical and other harsh environments, extending the anti-corrosion service life to more than 15 years.

3. Ultra-High Torque Bearing Capacity, Stable Heavy-Duty Operation

The gear shaft adopts integral forging forming technology, with a diameter increased by 20% compared with the standard model, and the keyway is reinforced by quenching, which significantly improves the torque bearing capacity. The rated output torque of B4FV reaches 48000-55000N·m, and the maximum allowable peak torque is 82500N·m, which can be perfectly matched with 45-500kW high-power motors. The integral cast steel housing with thickened wall (wall thickness ≥25mm) and reinforced flange design has excellent structural rigidity, no deformation under ultra-heavy load and impact, and the housing vibration amplitude is ≤0.2mm/s. The product adopts high-precision heavy-duty cylindrical roller bearings with double-row self-aligning function, which can bear large radial and axial loads, ensuring stable operation under 24-hour continuous heavy-duty working conditions, and the rated service life reaches more than 25 years under normal maintenance.

4. Customized Modular Installation, Adapt to Extreme Layout

Adopting customized modular design, supporting multiple installation modes such as offshore special flange-mounted (B5/B14/B35), torque arm-mounted with marine shock absorber, shaft-mounted with quick coupling and mobile base-mounted with anti-vibration pad, which can be flexibly adapted to the complex layout of offshore platforms, mining machinery and other equipment. The output shaft is available in two types: extra-large-diameter solid shaft (flat key/spline) and ultra-high-torque hollow shaft (locking disk connection), with shaft diameter ranging from 80mm to 180mm, which can be precisely matched with various heavy-duty working machines. The standardized marine interface design with reinforced anti-loosening connection parts facilitates quick installation and maintenance in harsh environments such as offshore and mining areas, reducing construction and maintenance time by 30% compared with traditional reducers.

5. Intelligent Thermal Management, Wide Temperature Adaptation

Equipped with intelligent temperature-controlled thermal management system, including multi-point temperature sensors, adaptive oil cooler and low-temperature heater, which can automatically adjust the lubricating oil temperature according to the working conditions. The optimized internal oil circuit with multi-point forced lubrication ensures sufficient lubrication of all transmission components under extreme heavy load. The housing is designed with large-area integral heat dissipation fins, and the heat dissipation efficiency is increased by 25% compared with ordinary models. The product can work normally in the operating temperature range of -50℃ to +140℃, and can adapt to the large temperature difference environment of offshore day and night and cold-region mining, avoiding equipment failure caused by excessive temperature or low-temperature frost.

III. Typical Application Fields: Focus on Extreme Heavy-Duty, Empowering Core Industries

With its exclusive heavy-duty impact-resistant, deep-sea grade anti-corrosion and ultra-high torque performance, Weigao HB-Series B4FV reducer has become the core transmission choice for extreme heavy-duty equipment, and its typical application fields include:

- Deep-Sea Oil and Gas Exploitation: Deep-sea drilling platform hoisting systems, underwater production equipment auxiliary transmission, adapting to 500m deep sea, high pressure, seawater corrosion and impact load environments;

- Offshore Engineering: Offshore wind power platform yaw systems, large offshore crane transmission, adapting to strong wind, waves, salt spray corrosion and alternating cold-heat environments;

- Heavy Open-Pit Mining: Large open-pit mine excavators, ultra-heavy-duty conveyor systems, adapting to heavy load, frequent impact, high dust and low-temperature environments;

- Chemical Heavy Industry: Large chemical reactor agitators, corrosive medium transportation pumps, adapting to high pressure, strong corrosion and continuous heavy-duty operation environments;

- Marine Engineering: Large shipborne crane systems, offshore oil transportation vessel auxiliary equipment, adapting to seawater corrosion, vibration and long-term navigation environment;

IV. Technical Parameters: Precise Matching, Meeting Diverse Needs

| Item | Specification Range |

| Motor Power Adaptation | 45kW - 500kW |

| Reduction Ratio | 10 - 600 (Single-stage/Multi-stage Combination) |

| Rated Output Torque | 48000N·m - 55000N·m (Maximum Peak Torque: 82500N·m) |

| Transmission Efficiency | 95% - 98.5% (Single-stage/Multi-stage) |

| Operating Noise | ≤65dB (Measured at 1m Distance) |

| Protection Level | IP69K (Customizable to IP68 Deep-Sea Immersion Protection) |

| Operating Temperature | -50℃ - +140℃ |

| Installation Method | Offshore Special Flange-mounted (B5/B14/B35), Torque Arm-mounted with Marine Shock Absorber, Shaft-mounted with Quick Coupling, Mobile Base-mounted with Anti-Vibration Pad |

| Output Shaft Type | Extra-Large-Diameter Solid Shaft (Flat Key/Spline), Ultra-High-Torque Hollow Shaft (Locking Disk Connection), Shaft Diameter: 80mm - 180mm |

V. Installation and Maintenance: Scientific Operation, Maximizing Performance

During installation, ensure that the coaxiality error between the reducer and the motor is ≤0.06mm to ensure impact resistance and transmission stability. For offshore and deep-sea installation, adopt marine-grade anti-corrosion fasteners and reinforced sealing measures, and install anti-vibration pads between the reducer and the base to reduce wave and equipment vibration impact. For deep-sea immersion installation, conduct pressure testing and sealing performance inspection in advance. Select the appropriate lubricating oil according to the working conditions: use 460# marine-grade heavy-duty anti-corrosion gear oil for normal temperature and heavy load, and 680# ultra-high-temperature anti-corrosion gear oil for high temperature and ultra-heavy load. Regularly check the oil level, oil quality, temperature sensor status, anti-corrosion coating integrity and fastener tightness; replace the lubricating oil after the first 1200 hours of operation, and perform comprehensive maintenance every 4500 hours thereafter, including checking bearing temperature, gear wear, sealing performance and housing deformation. If abnormal phenomena such as excessive noise, obvious vibration, oil leakage, overheating or torque fluctuation occur during operation, stop the machine immediately for inspection and troubleshooting.

VI. Conclusion: Extreme Heavy-Duty Transmission Leader, Creating Harsh Environment Value

Adhering to the design philosophy of "Extreme Heavy-Duty Adaptation, Deep-Sea Grade Protection, Stable and Efficient Transmission", Weigao HB-Series B4FV Industrial Gear Reducer focuses on the core transmission needs of extreme heavy-duty fields, integrating multiple exclusive technologies such as reinforced impact-resistant transmission, deep-sea grade anti-corrosion and intelligent thermal management. It breaks through the performance limitations of traditional reducers in harsh environments, providing stable, reliable and long-life power transmission solutions for deep-sea oil and gas exploitation, offshore engineering, heavy mining and other key industries. We will continue to rely on advanced extreme environment transmission technology, deeply explore the personalized needs of different extreme heavy-duty scenarios, provide customized technical support and global after-sales service, and work with customers to promote the progress of extreme heavy-duty industrial technology. All B4FV models have passed strict international certifications, fully complying with the technical standards and safety requirements of global extreme heavy-duty industries, and are committed to becoming a trusted partner in the global extreme heavy-duty transmission field.

Download

English

English