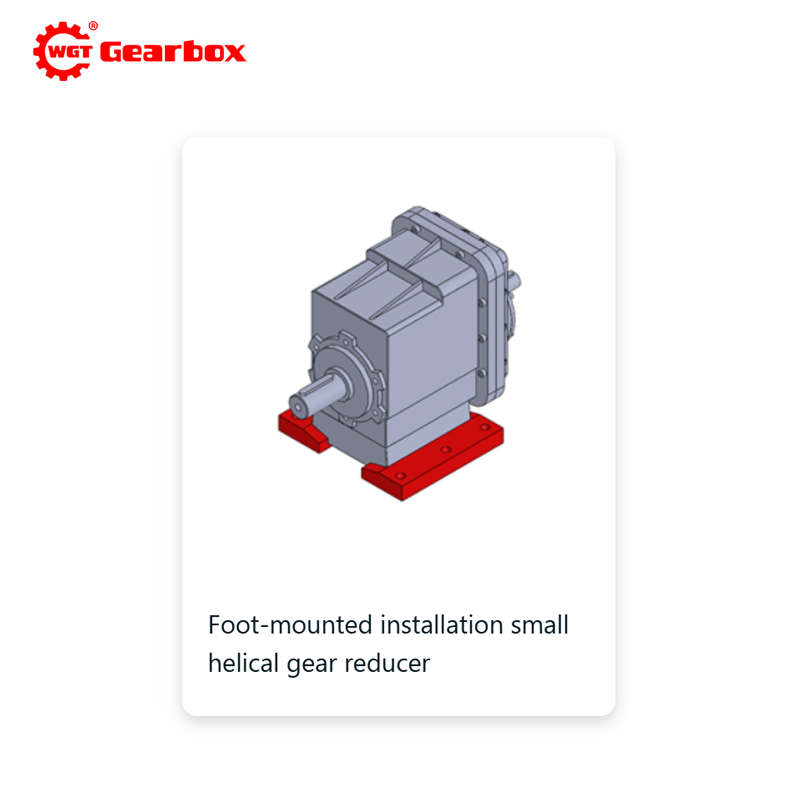

RC Series Helical Gear Units (Foot-Mounted): Compact & Lightweight Small-Scale Transmission Solution

I. Product Overview

Weigao RC Series Foot-Mounted Small Helical Gear Units are high-performance compact transmission devices tailored for small-scale industrial equipment requiring stable power output and space-saving installation. As a core product in Weigao's small transmission series, this unit is specifically designed to address the pain points of large volume, heavy weight, and poor installation compatibility of traditional reducers in small equipment scenarios. Compliant with international gear transmission standards and certified by ISO 9001 quality management system and IP54 protection level, it integrates precision parallel shaft helical gear transmission structure, lightweight reinforced cast iron housing, and universal foot-mounted interface. The product features compact structure, light weight, stable transmission, and strong adaptability, capable of stably operating in temperature ranges from -10℃ to +40℃. It is widely applied in small conveyors, precision small mixers, small fans, automatic small packaging machines, and laboratory equipment, providing efficient and reliable power transmission support for global small-scale industrial production and scientific research scenarios.

II. Core Advantages

1. Precision Compact Helical Gear Transmission, Efficient & Low Noise

Adopting one-stage precision parallel shaft helical gear transmission design optimized for small-scale equipment, the gear unit achieves stable power transmission with actual transmission ratios of 1.3:1 to 20:1 for flexible selection. Gears are made of high-quality 20CrMnTi alloy steel, processed by carburizing and quenching, and precision grinding, with tooth surface hardness reaching HRC 58-62 and roughness ≤Ra 0.8μm. The optimized tooth profile and micro-crowning technology ensure a meshing contact area of over 95%, effectively reducing transmission impact and noise. The no-load operating noise is ≤62dB at 1m distance, and the transmission efficiency is as high as 95%-97%, realizing energy-saving and quiet operation for small equipment. The compact transmission structure ensures that the overall volume is reduced by 35% compared with ordinary small reducers, easily fitting into the limited installation space of small equipment.

2. Universal Foot-Mounted Design, Flexible & Reliable Installation

The unit adopts a universal foot-mounted design, with a standardized base interface that is compatible with most small equipment frames. The base is designed with multiple precision positioning holes, which facilitates quick alignment and installation, and the installation accuracy error can be controlled within 0.1mm. The lightweight reinforced cast iron base has a reasonable rib structure, which not only reduces the overall weight by 25% compared with traditional cast iron bases but also ensures sufficient bearing capacity, effectively dispersing the transmission load to the equipment frame and avoiding deformation under rated working conditions. The foot-mounted design supports horizontal installation at multiple angles, adapting to different layout requirements of small equipment, and the installation process does not require complex tools, greatly improving installation efficiency.

3. High-Rigidity Cast Iron Housing, Reliable & Durable

The housing is made of lightweight reinforced HT200 cast iron, formed by precision casting and fine machining, balancing structural strength and lightweight requirements. The internal structure is optimized through finite element simulation, key stress-bearing parts are reasonably reinforced, and the overall rigidity is ensured while reducing weight. The surface is treated with anti-rust and anti-corrosion painting, which can adapt to general industrial environments such as dust and moderate humidity. Equipped with high-precision miniature deep groove ball bearings, the shaft system operates stably with low friction, and the service life exceeds 18,000 hours under normal working conditions. The sealed structure adopts high-quality wear-resistant oil seals, effectively preventing oil leakage and ensuring clean operation of small equipment.

4. Integrated Lubrication System, Convenient Maintenance

The gear unit adopts integrated oil bath lubrication design, with factory-filled special low-viscosity extreme pressure gear oil, enabling immediate use after installation. The housing is equipped with a small-sized transparent oil level observation window and a centralized oil filling/drain port, facilitating daily lubrication inspection and oil change operations even in narrow spaces. The lubrication system is optimized for long-term operation of small equipment, with a recommended oil change cycle of 5000 hours under normal working conditions, greatly reducing maintenance frequency and downtime cost. The lubricating oil has good low-temperature fluidity, ensuring stable lubrication even at low temperatures of -10℃.

III. Typical Application Fields

- Small Conveying Equipment: Mini belt conveyor drives, precision roller conveyor transmission mechanisms

- Small Mixing Equipment: Laboratory small mixers, miniature agitator transmission systems

- Lightweight General Machinery: Small axial flow fans, miniature water pump transmission mechanisms

- Packaging & Automation: Automatic small packaging machine drives, electronic component sorting machine auxiliary transmissions

- Scientific Research Equipment: Laboratory test benches, small-scale experimental device transmission systems

IV. Key Technical Parameters

| Model Specification | RC2, RC4, RC6, RC7, RC8, RC10, RC12, RC18, RC20, RC25 |

| Power Range | 0.12kW - 45kW |

| Transmission Ratio | 1.3:1 - 20:1 (actual ratio, stepless selection for small equipment) |

| Operating Noise | ≤65dB (1m distance, no-load) |

| Operating Temperature | -10℃ - +40℃ |

| Mounting Type | Universal foot-mounted (compatible with small equipment frame standards) |

V. Installation & Maintenance

Adopt universal foot-mounted standardized installation, ensure the flatness of the mounting surface ≤0.02mm/m and the levelness ≤0.03mm/m to avoid additional stress on the shaft system. During installation, use high-strength miniature bolts with anti-loosening washers to fix the base firmly on the equipment frame, and check the coaxiality between the input/output shaft and the connected small equipment to ensure smooth transmission. Select appropriate lubricating oil according to the working environment: use 150# low-viscosity extreme pressure industrial gear oil for normal temperature conditions. Regularly check the oil level through the observation window, and replace the lubricating oil every 5000 hours of operation or once a year. Keep the surface of the housing and base clean to facilitate heat dissipation. Stop the machine immediately for inspection if abnormal noise, oil leakage, or excessive temperature rise occurs during operation.

Weigao RC Series Foot-Mounted Small Helical Gear Units adhere to the design philosophy of "compactness, lightweight, and reliable adaptation", focusing on the core needs of small-scale industrial equipment and scientific research scenarios. With its advantages of small volume, light weight, stable transmission, and easy installation, it breaks through the limitations of traditional reducers in small equipment applications. The product provides efficient and reliable transmission solutions for small conveying, mixing, packaging, and laboratory equipment, supported by complete standardized small models and professional after-sales services. Compliant with international standards and industrial specifications, it is committed to becoming a trusted partner in the global small-scale industrial transmission field.

Download

English

English