WP Worm Gear Reducer (WPWDK/WPWDKA/WPWKS/WPWDKO/WPWDKT): Heavy-Duty Explosion-Proof Integrated Type & Intelligent Protection Transmission, Leading Hazardous Environment Applications

I. Product Overview: Explosion-Proof Integrated Configuration, Meeting Hazardous Environment Transmission Needs

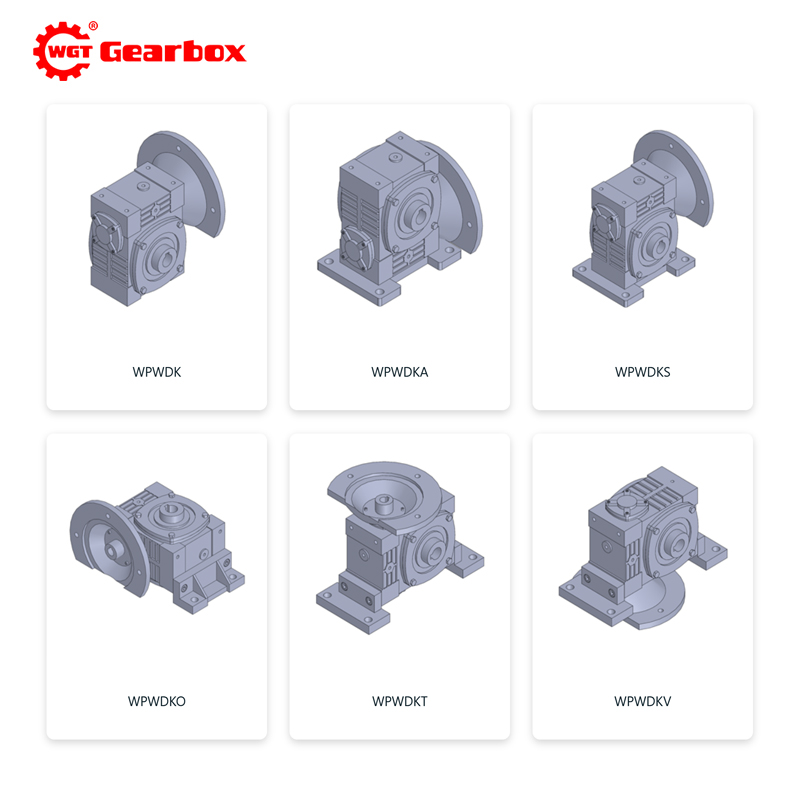

Weigao’s WP Series Worm Gear Reducers, covering core heavy-duty explosion-proof integrated models WPWDK, WPWDKA, WPWKS, WPWDKO and WPWDKT, are high-reliability power transmission devices specially developed for hazardous industrial scenarios requiring explosion-proof protection, heavy-load bearing, universal installation and intelligent monitoring. Targeting the pain points of traditional heavy-duty and servo-specific worm gear reducers such as lack of explosion-proof performance, poor environmental adaptability, and inability to realize real-time status monitoring in hazardous environments, this series integrates heavy-duty explosion-proof cabinet design, enhanced wear-resistant transmission technology, multi-layer intelligent sealing protection and real-time monitoring system. It realizes a perfect combination of explosion-proof safety guarantee, heavy-duty stable transmission, universal multi-attitude installation and intelligent fault early warning, and can stably operate in complex working conditions involving flammable and explosive gases/vapors, continuous heavy load, frequent impact and harsh environmental pollution. As a core transmission component for key hazardous environment equipment, this heavy-duty explosion-proof integrated WP series is widely applied in petrochemical storage and transportation, coal mine underground equipment, hazardous chemical mixing systems, gas processing plants and other industries, providing safe and reliable power support for global hazardous environment industrial production projects. The product has passed international certifications such as ATEX Ex d IIC T4 explosion-proof certification, ISO 9001 quality management system certification, and IP67 protection certification (customizable to IP68), and is trusted by more than 50 countries and regions for its excellent hazardous environment adaptation performance.

II. Core Advantages: Five Explosion-Proof Transmission Strengths, Defining Hazardous Environment Safety Standards

1. Heavy-Duty Explosion-Proof Cabinet, Multi-Attitude Safe Installation

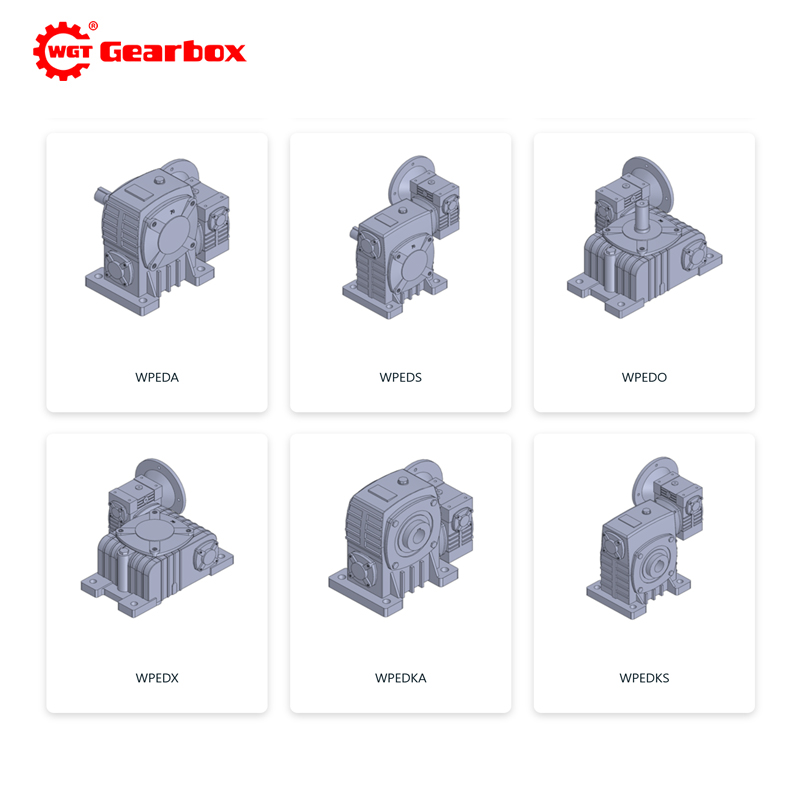

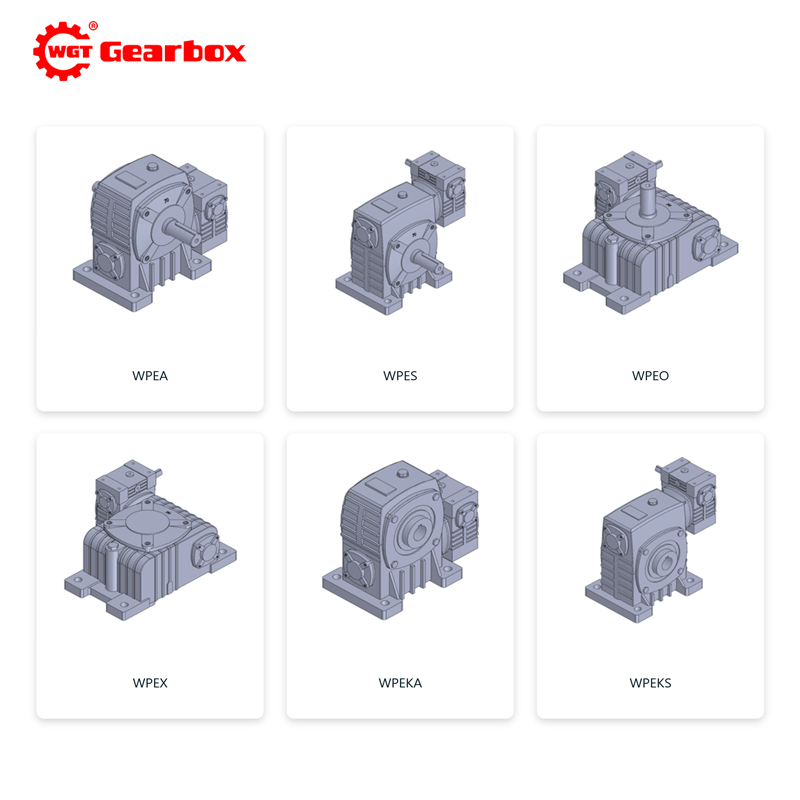

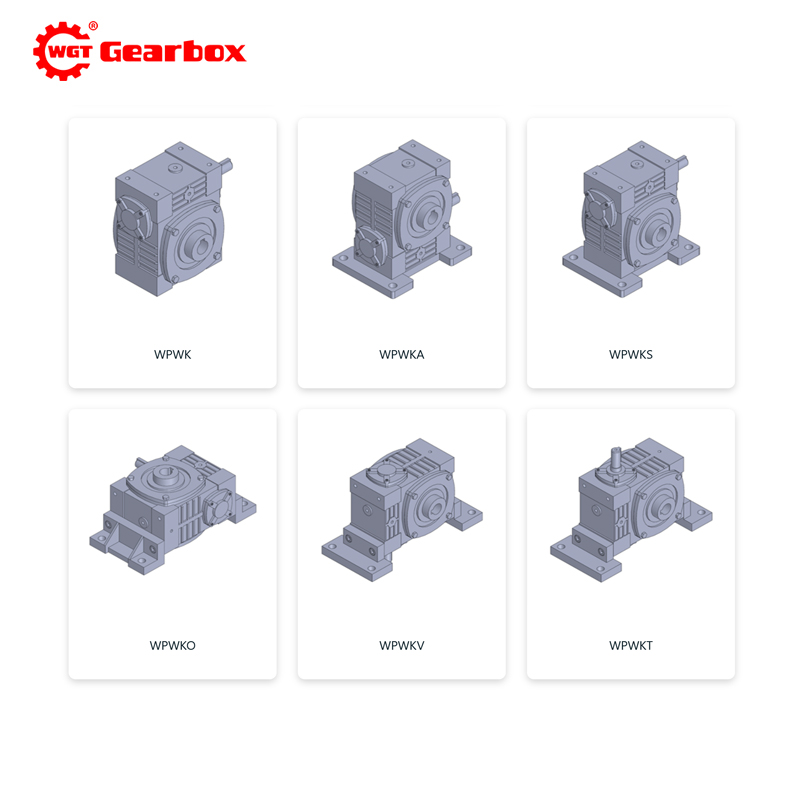

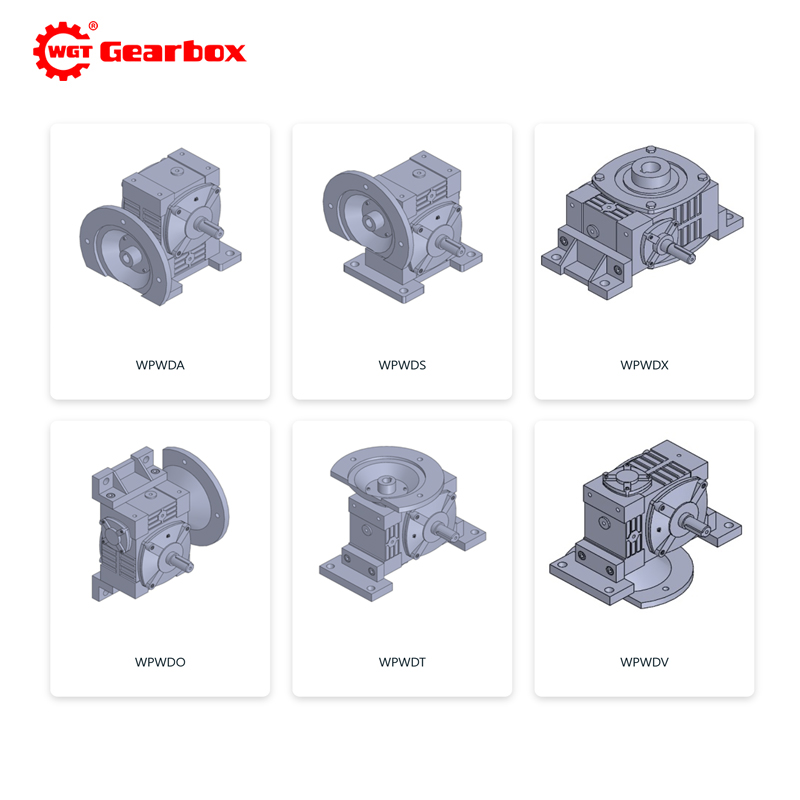

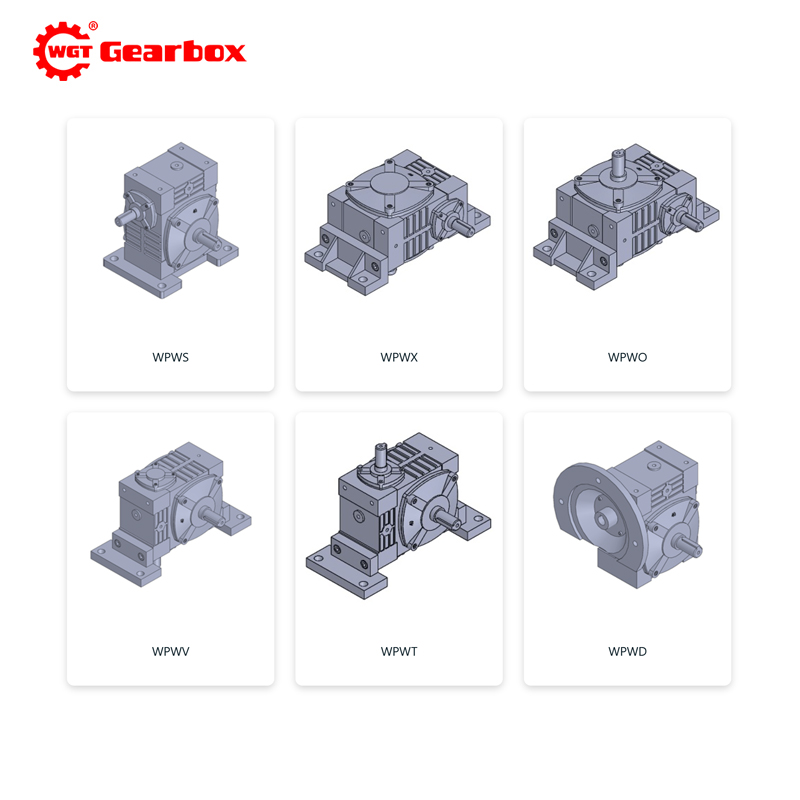

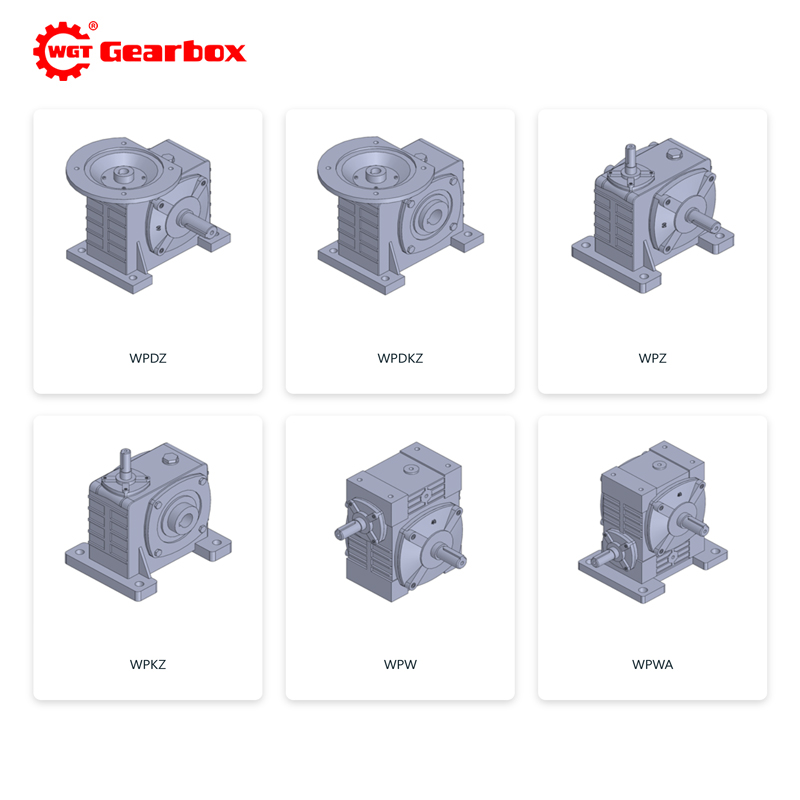

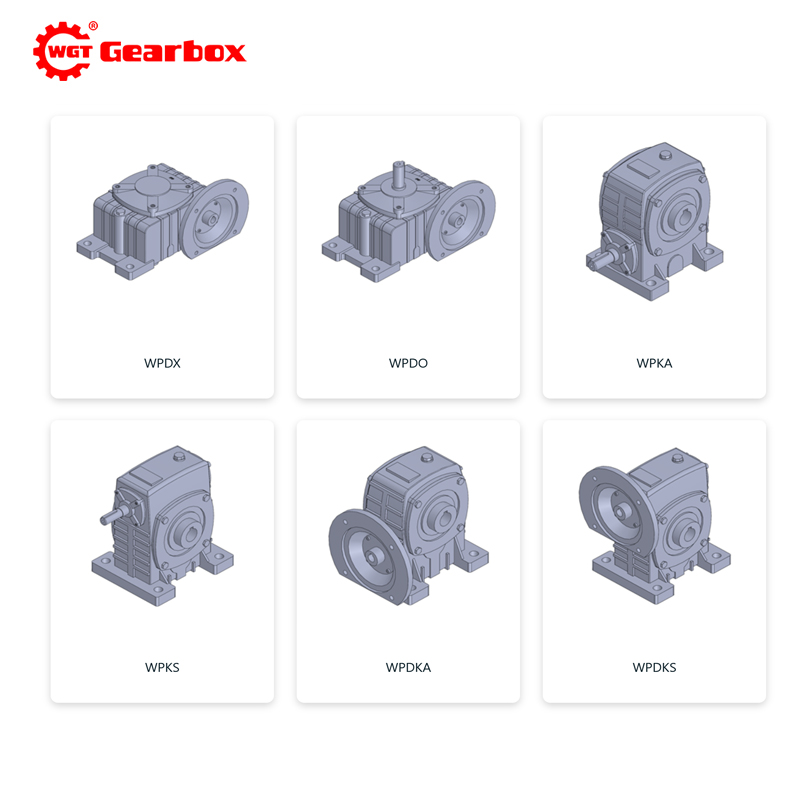

The series adopts a heavy-duty explosion-proof integrated cabinet structure optimized by bionic topology and finite element analysis, and the cabinet is made of high-strength cast iron (HT350) with thickened wall thickness (20% thicker than ordinary heavy-duty models) and dense reinforcing rib distribution, ensuring ultra-high structural rigidity and explosion-proof performance while realizing multi-attitude safe installation. The five core models cover diversified input-output attitudes to meet extreme hazardous environment equipment layout needs: WPWDK (standard heavy-duty explosion-proof type), WPWDKA (heavy-duty explosion-proof type with input shaft downward), WPWKS (heavy-duty explosion-proof type with input shaft upward), WPWDKO (heavy-duty explosion-proof type with output shaft upward), WPWDKT (heavy-duty explosion-proof type with vertical input/output shaft). The cabinet is equipped with reinforced explosion-proof mounting flanges and precision positioning holes on multiple sides, which can flexibly switch between horizontal, vertical, wall-mounted, ceiling-mounted and other installation modes. All joint surfaces adopt flameproof gap design (gap ≤0.15mm) to prevent flame leakage in case of internal ignition. The installation positioning accuracy error is ≤0.1mm, and the mounting base is designed with anti-vibration and anti-static gaskets, which effectively ensures the stable and safe operation of the transmission system under heavy-load vibration and static electricity accumulation conditions.

2. Enhanced Wear-Resistant Transmission, Strong Load-Bearing & Impact-Resistant

The series adopts enhanced heavy-duty explosion-proof worm gear transmission pair design, the worm is made of 20CrMnTi high-strength alloy steel, processed by integral forging, carburizing and quenching, and super-precision grinding, with surface hardness up to HRC 62-65 and tooth surface roughness ≤Ra 0.3μm. The worm gear is made of high-wear-resistant nickel bronze (ZCuNi10Pb1) with thickened tooth thickness and precision tooth profile modification, and the meshing contact area reaches more than 94%, realizing uniform force transmission under heavy load. The worm shaft adopts large-diameter integral rigid design, and the bearing adopts high-load self-aligning roller bearings with double-sided sealing and dust-proof cover, which improves the shaft system bearing capacity by 50% compared with ordinary heavy-duty models. The transmission accuracy error is ≤0.2arcmin, and the transmission system can bear 3.2 times the rated torque impact, with stable transmission accuracy deviation ≤0.25arcmin, which can perfectly match the heavy-load impact working conditions of petrochemical, coal mine and other hazardous industries. The no-load operating noise is ≤59dB, and the load operating noise is ≤66dB (measured at 1m distance), ensuring relatively quiet operation under heavy load and avoiding static electricity generation caused by excessive vibration.

3. Integrated Explosion-Proof Matching, Wide-Range Power Adaptation

The series supports integrated explosion-proof power source matching, and all models are equipped with standard explosion-proof motor flanges (compatible with IEC Ex standards) that can be directly matched with 2.2-90kW explosion-proof three-phase asynchronous motors, high-power variable frequency explosion-proof motors and flameproof servo motors. For special heavy-duty hazardous scenarios, it can be customized with reinforced explosion-proof flange structures and input/output shaft extension designs with explosion-proof sleeves to meet the matching needs of high-power heavy-duty explosion-proof motors. The flange and cabinet are integrally cast with coaxiality error ≤0.03mm, avoiding transmission efficiency loss caused by assembly errors. The explosion-proof junction box is integrated on the cabinet, which can directly connect the motor's explosion-proof circuit, simplifying the wiring process and avoiding potential safety hazards caused by external wiring. This integrated explosion-proof matching design not only improves the product's versatility and safety in hazardous environments, but also reduces the user's equipment procurement cost and debugging cycle.

4. Multi-Layer Intelligent Sealing & Efficient Heat Dissipation, Harsh Hazardous Environment Adaptation

The sealing system adopts enhanced five-layer intelligent protection design: outer layer stainless steel explosion-proof labyrinth seal + middle layer high-temperature resistant and corrosion-resistant double-lip oil seal + inner layer O-ring + bottom layer anti-dust and anti-corrosion cover + intelligent oil leakage monitoring sensor, with high-temperature resistant, corrosion-resistant and flame-retardant sealant at the cabinet joint, achieving IP67 protection level and customizable IP68 protection level for special harsh hazardous environments. It can effectively prevent the intrusion of flammable gases, corrosive media, dust and other impurities in petrochemical, coal mine and other harsh hazardous environments, and the intelligent sensor can timely alarm when oil leakage occurs, avoiding safety accidents caused by lubrication failure. The cabinet is designed with integral spiral heat dissipation fins, and the heat dissipation area is increased by 50% compared with ordinary heavy-duty models. It adopts optimized forced circulation lubrication with oil cooler, and the built-in high-precision oil filter and oil temperature sensor ensure the cleanliness and temperature stability of lubricating oil. Using 220#/320#/460# special heavy-duty explosion-proof synthetic worm gear oil, the product can work normally in the operating temperature range of -35℃ to +125℃, adapting to extreme temperature difference and hazardous gas environments.

5. Intelligent Status Monitoring, Low Maintenance & Safe Operation

The product is equipped with an intelligent status monitoring system, which can real-time monitor key parameters such as oil temperature, oil level, vibration amplitude and seal integrity through built-in sensors. The monitoring data can be transmitted to the remote control center through the RS485 communication interface, realizing remote fault early warning and status diagnosis, which is convenient for users to carry out predictive maintenance. The key components of the product adopt high-wear-resistant, high-temperature resistant and corrosion-resistant materials, and the worm gear and worm undergo special anti-corrosion and anti-static surface treatment to improve their adaptability to hazardous environments. The rated service life reaches more than 15 years under normal maintenance conditions, and the maintenance cycle is extended by 70% compared with ordinary heavy-duty models. The centralized explosion-proof oil filling port, large-diameter oil drain port and transparent explosion-proof oil level observation window facilitate daily lubrication management and maintenance operations without disassembling the explosion-proof structure. The overall maintenance cost is reduced by 40% compared with similar explosion-proof models, significantly saving the user's operation and maintenance costs.

III. Typical Application Fields: Focus on Hazardous Industry, Empowering Safe Production

With its exclusive heavy-duty explosion-proof protection, enhanced load-bearing transmission, harsh hazardous environment adaptation and intelligent status monitoring advantages, Weigao heavy-duty explosion-proof integrated WP Series Worm Gear Reducers have become the core transmission choice for hazardous environment industrial equipment, and their typical application fields include:

- Petrochemical Storage and Transportation: Oil depot conveying pump drives, chemical raw material transfer belt transmission systems, adapting to flammable and explosive gas environments, heavy load bearing and corrosion resistance requirements;

- Coal Mine Underground Equipment: Underground coal conveyor drives, mine ventilation fan transmission systems, adapting to high dust, high humidity, flammable gas and frequent impact working conditions;

- Hazardous Chemical Mixing Systems: Explosive chemical raw material mixer drives, toxic chemical reaction kettle auxiliary transmission systems, adapting to corrosive media, flammable and explosive environments and precise speed control requirements;

- Gas Processing Plants: Natural gas purification equipment drives, gas transmission pipeline booster pump transmission systems, adapting to flammable gas environments, continuous heavy load and low temperature working conditions;

IV. Technical Parameters: Precise Matching, Meeting Diverse Needs

- Pharmaceutical and Chemical Explosion-Proof Equipment: Explosive drug raw material processing equipment drives, chemical reagent packaging line transmission systems, adapting to clean and explosion-proof environments, low noise and stable operation requirements;

| Item | Specification Range |

| 2.2kW - 90kW | 1.5kW - 75kW |

| 10 - 80 (Single-stage); 100 - 1800 (Customized Double-stage) | 10 - 80 (Single-stage); 100 - 1500 (Customized Double-stage) |

| 1000N·m - 15000N·m (Graded by Model) | 800N·m - 12000N·m (Graded by Model) |

| 86% - 93% (Depending on Model and Reduction Ratio) | 85% - 93% (Depending on Model and Reduction Ratio) |

| ≤59dB - ≤66dB (Measured at 1m Distance) | ≤58dB - ≤65dB (Measured at 1m Distance) |

| Protection Level | IP67 (Customizable to IP68 for Special Environments), ATEX Ex d IIC T4 Explosion-Proof Certification |

| -35℃ - +125℃ | -30℃ - +120℃ |

| Horizontal-mounted, Vertical-mounted, Wall-mounted, Ceiling-mounted, WPWDK (Standard Heavy-Duty Explosion-Proof Type), WPWDKA (Heavy-Duty Explosion-Proof Type with Input Shaft Downward), WPWKS (Heavy-Duty Explosion-Proof Type with Input Shaft Upward), WPWDKO (Heavy-Duty Explosion-Proof Type with Output Shaft Upward), WPWDKT (Heavy-Duty Explosion-Proof Type with Vertical Input/Output Shaft) | Horizontal-mounted, Vertical-mounted, Wall-mounted, Ceiling-mounted, WPWK (Standard Heavy-Duty Universal Type), WPWKA (Heavy-Duty Universal Type with Input Shaft Downward), WPWKS (Heavy-Duty Universal Type with Input Shaft Upward), WPWKO (Heavy-Duty Universal Type with Output Shaft Upward), WPWKV (Heavy-Duty Universal Type with Input Shaft Vertical), WPWKT (Heavy-Duty Universal Type with Output Shaft Vertical) |

| Solid Shaft Output (Flat Key/Spline, Explosion-Proof Sleeve), Hollow Shaft Output (Locking Disk Connection, Explosion-Proof Type), Reinforced Shaft Extension (For High-Power Explosion-Proof Motor Matching) | Solid Shaft Output (Flat Key/Spline), Hollow Shaft Output (Locking Disk Connection), Reinforced Shaft Extension (For High-Power Motor Matching), Explosion-Proof Shaft Output (For Hazardous Environment) |

V. Installation and Maintenance: Scientific Operation, Maximizing Performance

During installation, select the corresponding model according to the equipment layout (input/output shaft attitude), explosion-proof grade requirements and load-bearing requirements. For hazardous environment installation scenarios, ensure that the coaxiality error between the reducer and the explosion-proof power source is ≤0.1mm, and use reinforced explosion-proof mounting brackets to fix firmly to avoid vibration and static electricity accumulation during operation. Strictly follow the explosion-proof installation specifications to ensure that all joint surfaces are free of damage and the flameproof gap meets the standard requirements. Select the appropriate explosion-proof grade lubricating oil according to the working conditions: use 220# special synthetic worm gear oil for normal temperature and general load, 320# for high temperature and heavy load, and 460# for ultra-heavy load and low temperature. Regularly check the oil level, oil quality, sealing performance, heat dissipation status and intelligent monitoring system; replace the lubricating oil after the first 2000 hours of operation, and perform comprehensive maintenance every 4000 hours thereafter, including checking worm gear meshing status, bearing temperature, fastener tightness, heat dissipation fin cleanliness and explosion-proof structure integrity. If abnormal phenomena such as excessive noise, vibration, oil leakage, overheating or intelligent alarm occur during operation, stop the machine immediately in a safe manner for inspection and troubleshooting.

VI. Conclusion: Hazardous Environment Transmission Leader, Empowering Safe Production Upgrade

Adhering to the design philosophy of "Explosion-Proof Safety, Heavy-Duty Bearing, Intelligent Monitoring and Harsh Environment Adaptation", Weigao heavy-duty explosion-proof integrated WP Series Worm Gear Reducers (WPWDK/WPWDKA/WPWKS/WPWDKO/WPWDKT) focus on the core transmission needs of hazardous environment industrial equipment, integrating multiple exclusive technologies such as heavy-duty explosion-proof cabinet design, enhanced wear-resistant transmission and intelligent status monitoring. It breaks through the performance limitations of traditional heavy-duty and servo-specific worm gear reducers in hazardous industrial multi-scenario applications, providing safe, stable and reliable power transmission solutions for petrochemical storage and transportation, coal mine underground equipment, hazardous chemical mixing systems and other key industries. We will continue to rely on advanced explosion-proof transmission technology, deeply explore the personalized needs of different hazardous industrial scenarios, provide customized product solutions and global after-sales service support, and work with customers to promote the upgrade of hazardous industrial production technology. All models of this heavy-duty explosion-proof integrated WP series have passed strict international certifications, fully complying with the technical standards and safety requirements of global hazardous industrial fields, and are committed to becoming a trusted partner in the global hazardous environment transmission field.

Download

English

English