F-Series Parallel Axis Helical Gear Reducer: Precision Transmission, Empowering Industrial High-Efficiency Operation

I. Product Overview: Customized Modular Design, Leading Transmission Performance

Weigao’s F-Series Parallel Axis Helical Gear Reducer, covering specialized models including FAZ..R, FAF..R, FA..R, F..R, FHZ, and FHF, is a high-precision power transmission solution tailored for diverse industrial parallel axis drive scenarios. Built on an upgraded modular platform, this series integrates refined helical gear processing technology and optimized structural layout, realizing a perfect synergy of compact size, high torque density and low noise operation. It effectively overcomes the shortcomings of traditional parallel axis reducers such as poor adaptability to complex working conditions and low transmission precision, and can maintain stable and reliable power output in both intermittent and continuous operation modes. With its model-specific design advantages and broad compatibility, it has become a core transmission component in industries like intelligent manufacturing, automotive parts processing, food & beverage packaging, and textile machinery, providing solid support for the upgrading of industrial production towards refinement and intelligence. As a key export product of Weigao, this series has been sold to over 80 countries and regions globally, gaining wide recognition from international customers with its tailored performance.

II. Core Advantages: Six Core Strengths, Shaping Transmission Excellence

1. High-Precision Transmission, Stable Operation

Adopting high-precision grinding helical gears with advanced tooth profile correction technology, the series achieves meshing accuracy up to GB/T 10095.2 Class 5 standard. The parallel axis layout with optimized center distance ensures uniform force distribution during gear meshing, reducing transmission backlash to ≤3arcmin (customizable to ≤1arcmin for precision models). The transmission efficiency reaches 95%-98% for two-stage transmission and 93%-96% for three-stage transmission, minimizing power loss. The smooth meshing characteristics of helical gears keep operating noise ≤70dB at 1m distance, creating a quiet and efficient production environment.

2. Model-Specific Optimization, Strong Adaptability

Each model in the series is optimized for targeted scenarios: FAZ..R and FAF..R models are designed for high-speed precision transmission, ideal for automated production lines; FA..R models excel in medium-load continuous operation, suitable for general manufacturing equipment; F..R models feature enhanced load-bearing capacity, adapting to heavy-duty processing scenarios; FHZ and FHF models are equipped with special sealing structures, optimized for dusty and humid working environments. This targeted design ensures that each model can exert optimal performance in its respective application scenario.

3. Robust Load-Bearing Capacity, Long Service Life

Gears and shafts are made of high-strength 20CrMnTi alloy steel, processed through integral carburizing, quenching and precision grinding, with surface hardness up to HRC 60-64 and core hardness HRC 30-35, ensuring excellent wear resistance and impact toughness. The optimized gear tooth width design increases the effective meshing area by 35% compared to standard models, with rated output torque ranging from 80N·m to 12000N·m. The one-piece cast iron housing with rib reinforcement design enhances structural rigidity, effectively dispersing transmission stress and preventing deformation, ensuring a service life of over 12 years under normal maintenance.

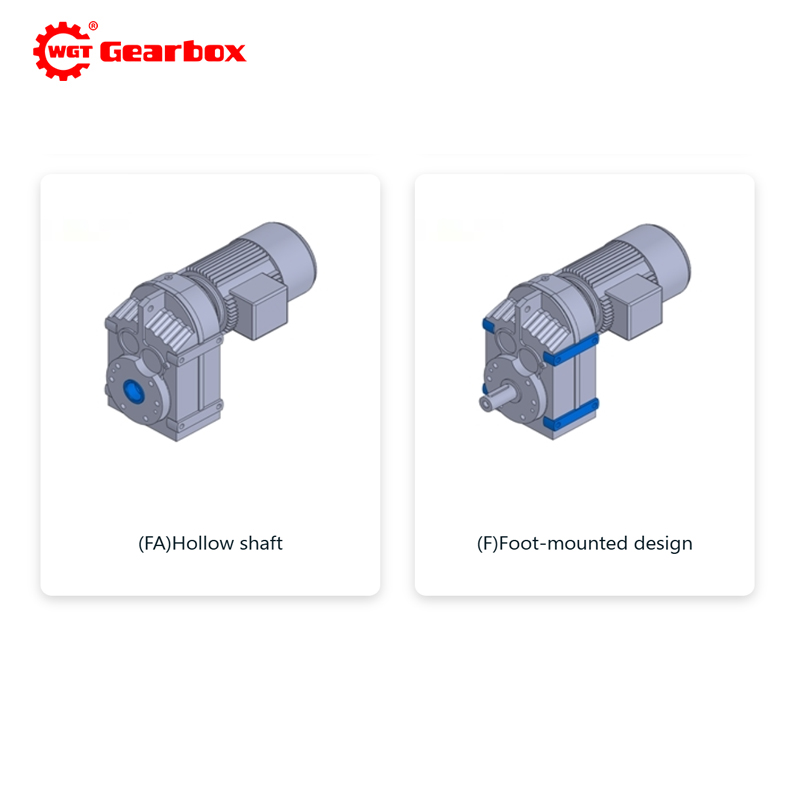

4. Flexible Installation, Easy Configuration

The series supports multiple installation modes including base-mounted, flange-mounted (B5/B14), and torque arm-mounted, compatible with various motor connection methods. The output shaft offers diverse configurations such as solid shaft with flat key, spline solid shaft, hollow shaft with locking disk, and hollow shaft with involute spline. It can be flexibly matched with motors of 0.25kW-110kW power and reduction ratios of 2.5-360 (two-stage/three-stage combination), meeting the personalized configuration needs of different equipment.

5. Advanced Sealing System, Wide Environmental Adaptability

Equipped with a composite sealing structure of double-lip oil seal + labyrinth seal + O-ring, the reducer achieves IP55 protection level (IP65 available for customization). This structure effectively blocks the intrusion of dust, moisture and corrosive media, ensuring stable operation in harsh environments such as high temperature, high humidity and dusty workshops. The rational internal oil circuit design and forced lubrication option (for high-speed models) ensure sufficient lubrication of all transmission components, enabling normal operation in the temperature range of -30℃ to +90℃.

6. Convenient Maintenance, Cost-Saving Operation

The modular design enables quick disassembly and assembly of components, with high interchangeability of spare parts, greatly reducing maintenance time and labor costs. Centralized oil filling and drainage ports and oil level observation windows facilitate daily lubrication management; it is recommended to use 220#/320# industrial gear oil, with oil change intervals of 500 hours for the first use and 6000 hours for subsequent regular maintenance. The high reliability and long service life of the product significantly lower the total cost of ownership for customers.

III. Application Fields: Targeted Coverage, Boosting Industry Upgrade

With its model-specific advantages and excellent overall performance, Weigao’s F-Series Parallel Axis Helical Gear Reducer has been widely applied in targeted industrial fields:

- Intelligent Manufacturing: Automated assembly lines, robotic arms, precision machining centers, providing high-precision and stable power transmission;

- Automotive Parts Processing: Gear hobbing machines, stamping equipment, welding robots, adapting to high-frequency and high-precision production needs;

- Food & Beverage Packaging: Bottle filling machines, carton packaging lines, conveyor systems, ensuring clean and efficient operation;

- Textile Machinery: Spinning machines, weaving machines, printing and dyeing equipment, adapting to continuous and low-noise operation requirements;

- General Machinery: Ventilation fans, water treatment pumps, mixer equipment, optimizing transmission efficiency and reducing energy consumption.

IV. Technical Parameters: Precise Matching, Meeting Diverse Needs

| Item | Specification Range |

| Motor Power Adaptation | 0.25kW - 110kW |

| Reduction Ratio | 2.5 - 360 (Two-stage/Three-stage Combination) |

| Rated Output Torque | 80N·m - 12000N·m |

| Transmission Efficiency | 93% - 98% (Two-stage/Three-stage) |

| Operating Noise | ≤70dB (Measured at 1m Distance) |

| Protection Level | IP55 (IP65 Customizable) |

| Operating Temperature | -30℃ - +90℃ |

| Installation Method | Base-mounted, Flange-mounted (B5/B14), Torque Arm-mounted |

| Output Shaft Type | Solid Shaft (Flat Key/Spline), Hollow Shaft (Locking Disk/Involute Spline) |

V. Installation and Maintenance: Scientific Operation, Maximizing Performance

During installation, ensure the coaxiality error between the reducer and the motor is ≤0.1mm and the parallelism error ≤0.08mm to avoid abnormal wear of gears. Select lubricating oil according to the working temperature: use 220# industrial gear oil for normal temperature (0℃-40℃) and 320# for high temperature (40℃-90℃). Check the oil level regularly to ensure it is within the standard range; replace the oil after the first 500 hours of operation, and perform comprehensive maintenance every 6000 hours, including checking gear meshing status, sealing performance and tightening fasteners. If abnormal phenomena such as excessive noise, overheating or oil leakage occur, stop the machine immediately for inspection and troubleshooting.

VI. Conclusion: Innovation-Driven, Creating Value for Customers

Adhering to the design philosophy of "Precision, Stability, Efficiency and Durability", Weigao’s F-Series Parallel Axis Helical Gear Reducer (FAZ..R, FAF..R, FA..R, F..R, FHZ, FHF) continuously upgrades technology and optimizes processes to meet the increasingly diversified and high-end transmission needs of the industrial field. With its model-specific advantages, reliable performance and flexible configuration, the series provides efficient transmission solutions for various industries, helping customers improve production efficiency and reduce operation costs, and becoming a trusted partner in the industrial upgrading process. We will continue to focus on customer needs, deepen the research and development of transmission technology, provide customized solutions and global after-sales services, and work with customers around the world to build a more intelligent and efficient industrial ecosystem. All export products have passed international certifications such as ROHS, CE and ISO9001, fully complying with the technical and safety standards of different countries and regions.

Download

English

English