Navigating Industrial Power: A Comprehensive Guide to Motors, Suppliers, and Key Components

Introduction to Industrial Motors and Their Importance

Industrial motors are the backbone of modern machinery, powering everything from manufacturing lines to heavy equipment. Choosing the right motor can significantly impact operational efficiency, energy consumption, and safety. In this article, we'll delve into key motor types and components, helping you make informed decisions when working with a motor supplier or motor manufacturer.

Key Motor Types for Various Applications

Different industrial tasks require specific motor designs. A variable frequency motor is essential for applications needing precise speed control, such as conveyor systems or pumps, as it allows for energy savings by adjusting the motor's frequency. For safety-critical operations, a brake motor provides immediate stopping power, preventing accidents in equipment like elevators or cranes. In hazardous environments, an explosion-proof motor is non-negotiable, designed to contain sparks and prevent ignition in areas with flammable gases or dust.

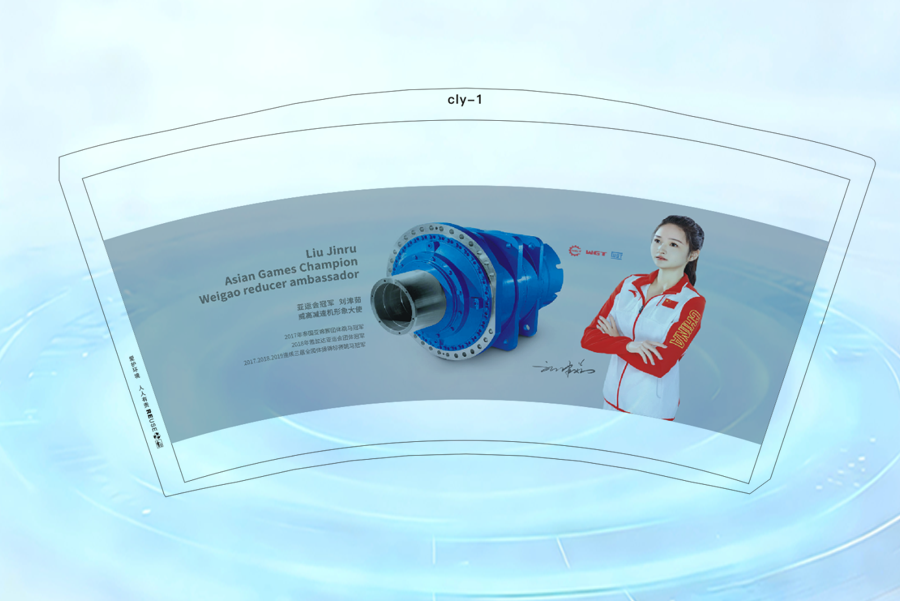

The Role of Gearboxes in Motor Systems

A gearbox is often paired with motors to adjust torque and speed, enhancing performance in applications like robotics or automotive systems. By reducing motor speed while increasing torque, gearboxes ensure that machinery operates efficiently under varying loads. When selecting a gearbox, consider factors like gear ratio, material durability, and compatibility with your motor type to avoid premature wear and downtime.

Choosing a Reliable Motor Supplier or Manufacturer

Partnering with a reputable motor supplier or motor manufacturer is key to obtaining high-quality components. Look for providers with certifications, such as ISO standards, and positive customer reviews. For instance, WGTmotor.com is known for offering a wide range of motors, including specialized types, and providing technical support. Always verify product specifications, warranty terms, and after-sales service to ensure long-term reliability.

Practical Tips for Motor Selection and Maintenance

To maximize motor lifespan, conduct regular maintenance checks, such as inspecting bearings and lubricating moving parts. For a variable frequency motor, ensure proper installation of frequency drives to avoid electrical issues. When using a brake motor, test the braking mechanism periodically to maintain safety. In the case of an explosion-proof motor, follow strict environmental guidelines and use certified enclosures. Consulting experts from a trusted supplier like those at WGTmotor.com can provide tailored advice.

Common Questions

What is the main advantage of a variable frequency motor?

A variable frequency motor offers precise speed control and energy efficiency by adjusting the electrical frequency, reducing power consumption in applications with varying loads.

How do I choose between a motor supplier and a manufacturer?

A motor supplier typically distributes products from various manufacturers, offering a broad selection, while a manufacturer produces motors directly, often providing customization options. Consider your specific needs for variety versus specialized support.

Why is a gearbox important in motor systems?

A gearbox optimizes motor performance by converting high-speed, low-torque output into low-speed, high-torque motion, essential for tasks requiring heavy lifting or precise movement.

What safety features should I look for in an explosion-proof motor?

Look for motors with robust enclosures that prevent sparks from escaping, certifications like ATEX or UL for hazardous areas, and materials resistant to corrosion and heat.

Can I find all these motor types on WGTmotor.com?

Yes, WGTmotor.com offers a comprehensive catalog including variable frequency, brake, and explosion-proof motors, along with gearboxes, making it a convenient one-stop shop for industrial components.