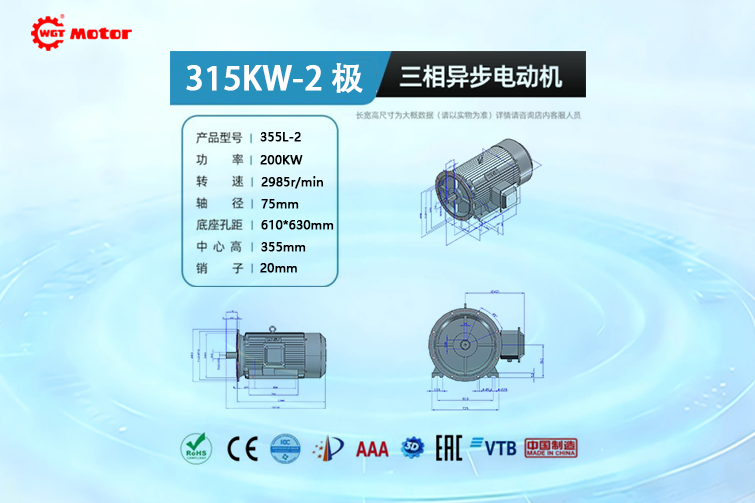

315KW 2-pole 2985rpm Drawings

Product Introduction of 315KW 2-Pole 2985rpm Three-Phase Induction Motor

This 315KW 2-pole 2985rpm three-phase induction motor realizes efficient conversion of electrical energy to mechanical energy based on the core principle of electromagnetic induction. When three-phase alternating current is supplied to the stator windings, a high-speed rotating magnetic field with a synchronous speed of 3000rpm is instantly generated. This magnetic field cuts the rotor conductors, inducing electromotive force and induced current in the rotor, which drives the rotor to rotate stably under the action of electromagnetic force. Its rotor speed of 2985rpm is slightly lower than the synchronous speed, ensuring ultra-smooth and continuous power output for high-speed industrial scenarios, with excellent operational stability and low noise levels.

Structurally optimized for high-speed stability and heavy-load endurance, the motor adopts a lightweight yet high-rigidity integrated cast iron frame. The stator is laminated with high-grade low-loss silicon steel sheets through precision stamping and lamination technology, minimizing iron loss and improving magnetic conductivity to enhance overall energy efficiency. The windings are made of high-quality Class F insulation materials, combined with vacuum impregnation and precision winding processes, greatly boosting heat resistance and insulation reliability, enabling continuous full-load operation without insulation breakdown even in high-temperature environments.

The rotor features a low-rotational-inertia cast aluminum squirrel-cage structure, with conductor bars and end rings integrated by one-time casting. This design ensures high mechanical strength, quick start-up response and excellent dynamic performance, allowing the motor to cope with frequent start-stop and sudden load changes. Key performance parameters are optimized: rated power 315KW, rated speed 2985rpm, rated torque up to 1008N·m, and the scientific ratio of starting torque to maximum torque guarantees stable start-up under medium loads. Complying with GB1 energy efficiency standard, it has a power factor of ≥0.89, with strictly controlled no-load and load losses for remarkable energy-saving effects.

Equipped with high-precision sealed rolling bearings and an optimized lubrication system, the motor reduces friction loss, extends service life and lowers maintenance costs. The optional IP54/IP55 protection level adapts to dusty, moderately humid industrial environments. Widely applied to high-speed equipment like centrifugal fans, air compressors and centrifugal pumps in petrochemical, power generation and metallurgy industries, it serves as a reliable and high-efficiency power core for modern industrial production.